Sammic is known as a brand that provides modern and prestigious kitchen equipment in the industry from Spain. Each product from the Sammic name always carries the highest level of reliability, quality and perfection. In modern cooking techniques, vacuum technology is very interested, because of its ability to ensure the quality and keep the nutrients of the food. For the same reason, vacuum packaging machine is considered an extremely necessary business kitchen support tool. In this article, Cosmic would like to introduce to you Sammic’s SU-604 series with large size suitable for industrial kitchens with large capacity.

1. Sammic’s modern vacuum technology

Vacuum packaging is a common method of removing oxygen from the product’s packaging, preventing oxidation from fermenting the inside of the food. This technology is often applied to preserve raw and unprocessed foods, pharmaceuticals, dry goods, etc. to prolong storage and use time. Especially Sammic’s SU series can absorb liquid food.

Vacuum technology is being popular and widely used in industrial kitchens today

Vacuum technology is no longer applied in the slow cooking method of modern industrial kitchens. Vacuum to keep all the nutrients of the food completely, cooked by centrifugal wave temperature in the water stream. Therefore, this cooking method will help the food to be cooked evenly, more correctly.

2. Sammic-SU 604 Series Features

Total load capacity of 1100W with stable 3-phase power requirement, noise level (1m.): 75 dB(A) and limited background noise: 32 dB(A) make it streamlined.

The Sammic SU-604 industrial vacuum packer is designed to allow for customizing suction power, optionally with a setting function of up to 10 seconds of enhanced vacuum, and memory programming of 25 programs.

The SU series is a color display, easier to operate the functions, and this series is suitable for liquid food such as sauce, soup, food containing oil. This is different for the SE series.

The compartment and body are made of stainless steel, the power cord is designed to be completely hidden under the shell to make it safer and easier to use and clean.

By replacing the double sealing bar with the bag cutter, the diverticulum is automatically cut at the moment it is sealed.

The holder allows liquids to be placed in the proper position for packing, preventing them from spilling in the process.

Sammic packaging machines are certified by NSF International in compliance with NSF/ANSI standards, in itself, a guarantee of hygiene.

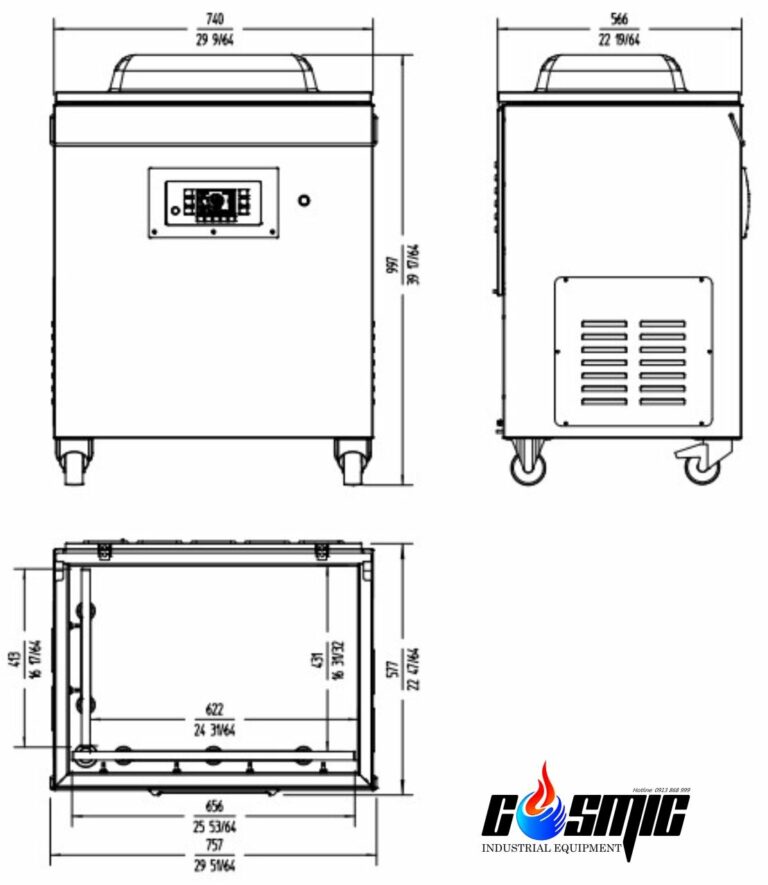

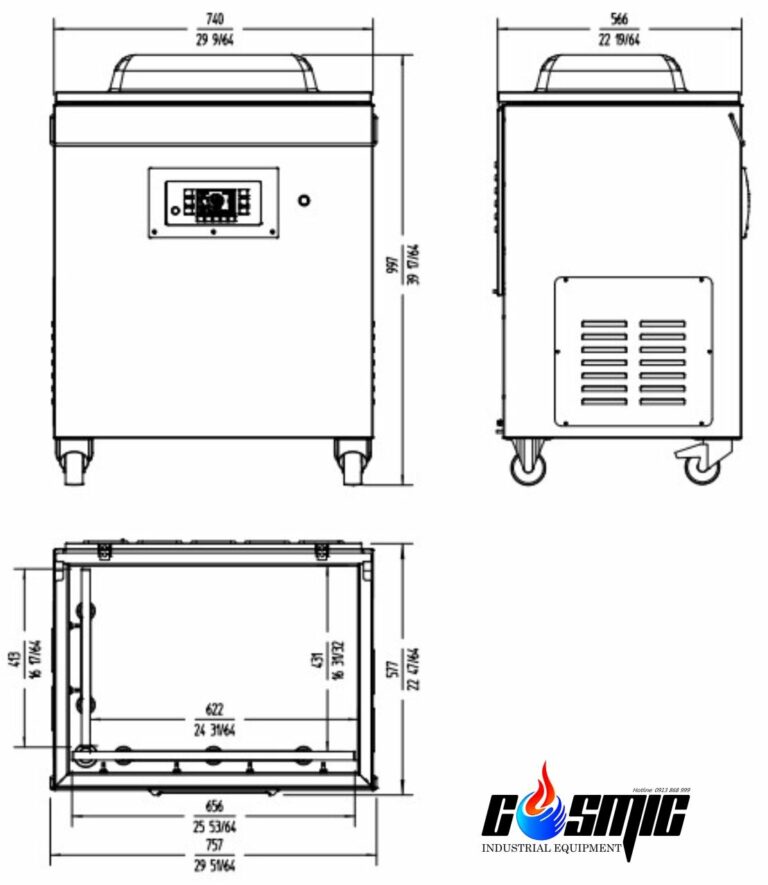

Detail structure of Su-604 vacuum machine

Equipped with Busch’s air inflator system and dedicated dual stamping bar that seals the bag, doubling the packaging’s durability. By replacing the dual sealing bar with the bag cutter kit, the diverticulum is automatically cut at the moment it is sealed.

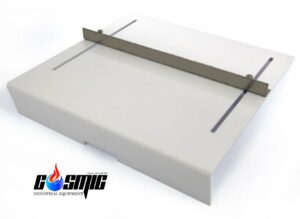

The pads, made of high quality polycarbonate, have a dual purpose. On the one hand, they allow the product to be positioned at the proper height for a perfect sealing. On the other hand, as there is less air in the chamber, better performance is achieved during the encapsulation process, as it allows to shorten the time to achieve the desired vacuum.

The product can be accompanied by optional tools such as: Sammic high-grade vacuum plastic bag, Vacuum extractor, Bag trimming bar, Liquid bag disc, etc., according to the needs of the business. These attached products will help the vacuum cleaner become much more modern.

The SU series features an easy-to-use design, convenient operation and a variety of sizes from standard to compact, to suit a variety of needs and features. In particular, the leading thermal sensor from Sammic integrated in the machine operation technology will help the manipulation and packaging of products to be controlled more precisely. Intuitive controls right on the body help control all parameters while in use. You can watch the user guide through the specific video below!